Save Time + Money on Install with Staple Wasp

Staple Wasp engineered a better way to install erosion blankets, landscape fabric and driplines with a staple gun. The installation process is faster, uses less labor, improves installation quality and reduces the physical impacts on crews in the field.

In 2011, Sam Herrmann and Gene Fisher set out to improve standard staple guns, which did little to make installation faster because they were heavy and hard to use. The parts on traditional tools wore out quickly, so they had to be replaced every season.

With feedback from contractors who tested their prototype, theydeveloped a lighter staple gun that can still hold up to the demands of daily use. Its access chamber and patented removable jam plate let users access the chamber in a matter of seconds—without the tools needed for most models and without slowing down progress.

Most staple tension feeds vary depending on the number of staples in the chamber, but the Staple Wasp’s patented constant tension spring keeps pressure in the chamber no matter how many staples are left. Plus, their 6” 13-gauge staples are held together in the magazine with a special glue and adhering process that prevents individual staples from getting jammed in the chamber.

When standard staple guns stop working, they need to be replaced entirely. The Staple Wasp is built to be a long-term solution with all replaceable parts that can be ordered directly from the company.

Staple Wasp comes with a patented soft ground shoe attachment that provides more pressure and a broader surface area contact to secure the staple without sinking into soft soil. It also keeps the staple chamber clean, even in dirty conditions.

Their patented irrigation shoe attachment can be purchased separately to replace the ground shoe attachment for drip hose installation.

Installing erosion blankets, landscape fabric and driplines is a tough job. Make it easier for your crews with Staple Wasp.

Visit www.staplewasp.com to learn more.

Staple Wasp is manufactured in the U.S.

- Dimensions of the gun: 42” height x 14” length x 16” curved handle width/3 ½” at base

- Weight of the gun: 13.5 lbs.

- Staple magazine capacity: 1 clip of 50 steel or galvanized staples

- Material used: Aluminum and hardened steel

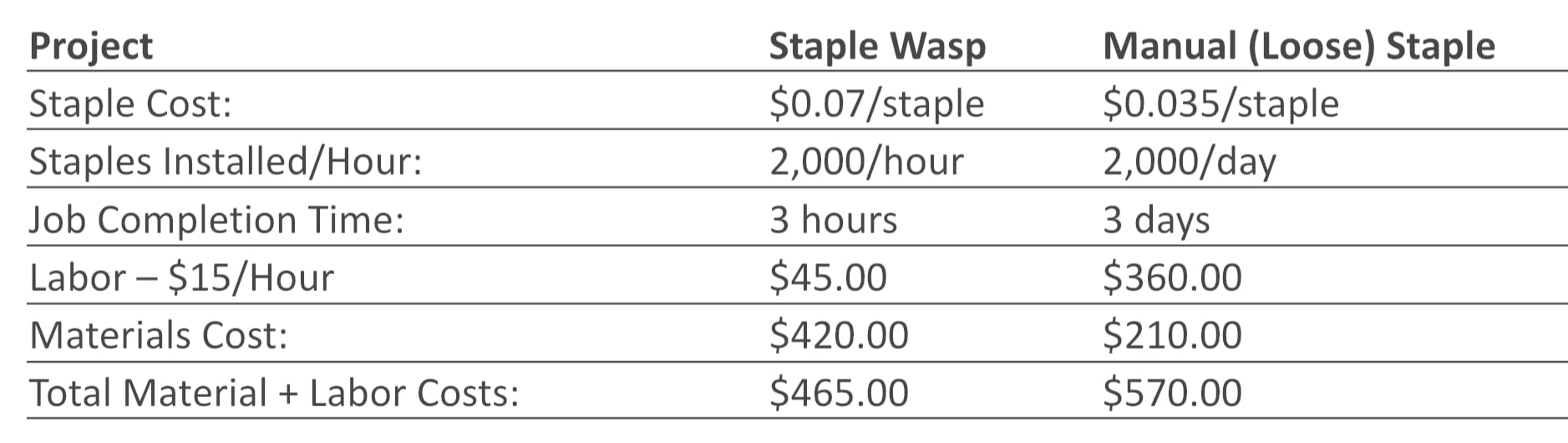

How Staple Wasp Pays for Itself

Job Cost Data: Staple Wasp vs. manual staple installation

Job Analysis: 6,000 staple project/1 person install

CONTACT

Gene Fisher

Tel: 612-816-7520

.png?width=541&height=218&name=synkd%20logo%20w%20tagline%20(2).png)

Anne-Marie Fruge

Anne-Marie Fruge